|

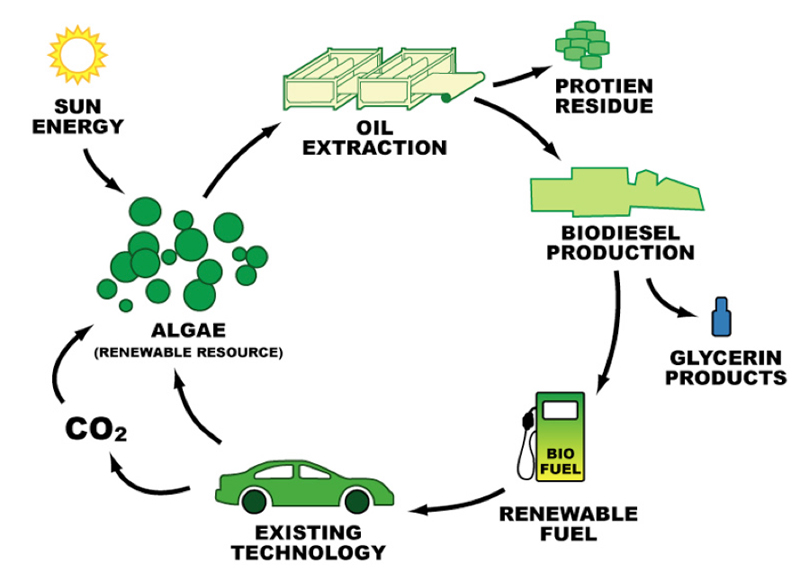

What is Biodiesel? Biodiesel is a domestically produced, renewable fuel that can be manufactured from vegetable oils, animal fats, or recycled restaurant grease for use in diesel vehicles. Biodiesel’s physical properties are similar to those of petroleum diesel but it is a cleaner-burning alternative. It can be used in existing diesel engines without modification and is covered by all major engine manufacturers’ warranties

|

|

How is Biodiesel Used?

Biodiesel can be blended and used in many different concentrations, including B100 (pure biodiesel), B20 (20% biodiesel, 80% petroleum diesel), B5 (5% biodiesel, 95% petroleum diesel) and B2 (2% biodiesel, 98% petroleum diesel). B20 is a common biodiesel blend in the United States.

B100 (pure biodiesel)

B100 and other high-level biodiesel blends are less common than B20 and lower blends due to a lack of regulatory incentives and pricing. B100 can be used in some engines built since 1994 with biodiesel-compatible material for certain parts, such as hoses and gaskets. B100 has a solvent effect, and it can clean a vehicle’s fuel system and release deposits accumulated from petroleum diesel use. The release of these deposits may initially clog filters and require frequent filter replacement in the first few tanks of high-level blends.

B20 (20% biodiesel, 80% petroleum diesel)

B20 is the most common biodiesel blend in the United States. B20 is popular because it represents a good balance of cost, emissions, cold-weather performance, materials compatibility, and ability to act as a solvent. Most biodiesel users purchase B20 or lower blends from their normal fuel distributors or from biodiesel marketers. Regulated fleets that use biodiesel blends of 20% (B20) or higher qualify for biodiesel fuel use credits under the Energy Policy Act of 1992.

B5 (5% biodiesel, 95% petroleum diesel)Low-level biodiesel blends, such as B5 are ASTM approved for safe operation in any compression-ignition engine designed to be operated on petroleum diesel. This can include light-duty and heavy-duty diesel cars and trucks, tractors, boats, and electrical generators.

B2 (2% biodiesel, 98% petroleum diesel)

Blends like B2 and B5 are popular fuels in the trucking industry because biodiesel has excellent lubricating properties, so usage of the blends can benefit engine performance.

What Are the Benefits?

Biodiesel is made from renewable resources and has lower emissions compared to petroleum diesel so it’s better for the environment. It is less toxic than table salt and biodegrades as fast as sugar. Produced domestically with natural resources, its use decreases our dependence on imported fuel and contributes to our own economy. Biodiesel is one of several alternative fuels designed to extend the usefulness of petroleum, and the longevity and cleanliness of diesel engines.

A U.S. Department of Energy study showed that the production and use of biodiesel, compared to petroleum diesel, resulted in a 78.5% reduction in carbon dioxide emissions.

What are the emissions reductions gained from biodiesel?

Particulate Matter (PM): 12% reduction with B20, 48% reduction with B100

Carbon Monoxide (CO): 12% reduction with B20, 48% reduction with B100

Carbon Dioxide (CO2): 16% reduction with B20, 78% reduction with B100 (life-cycle reduction)

Hydrocarbons (VOCs): 20% reduction with B20, 68% reduction with B100

Nitrogen Oxides (NOx): +/- 1-2% change with B20 or B100

Sulfur Dioxide (SOx): 20% reduction with B20, 100% reduction with B100

Resources

Considering biodiesel for your fleet?

Choosing the right fuel for your fleet is a big decision, and we believe knowing the benefits of biodiesel will help you make the decision to reduce petroleum use. Renewable Energy Group (REG) has put together this overview and you can download it here:

Topics covered…

- What biodiesel is

- Key terminology associated with the fuel

- The performance benefits of biodiesel

- How biodiesel reduces emissions

REG also spoke to Green Fleet Radio about biodiesel: Give it a listen

If you wish to have a conversation with REG, please contact us.

Metropolitan Washington Council of Governments (COG’s) new Electric Vehicle (EV) Deployment Clearinghouse provides a suite of tools & resources to aid localities as they work to facilitate EV adoption. Learn more about the resource and how it can help achieve regional climate goals: https://bit.ly/43uRIUy

Basics of Electric (EVs)

The District Department of Transportation (DDOT) has a pilot electric bus fleet, which won the GWRCCC 25th Anniversary Electric Fleet of the Year Award .

|

About Electric Vehicles

Hybrid Electric Vehicles (HEVs)

Hybrid electric vehicles (HEVs) are powered by an internal combustion engine or other propulsion source that can be run on conventional or alternative fuel and an electric motor that uses energy stored in a battery. HEVs combine the benefits of high fuel economy and low emissions with the power and range of conventional vehicles.

Plug-In Hybrid Electric Vehicles (PHEVs)

Plug-in hybrid electric vehicles (PHEVs) use batteries to power an electric motor and use another fuel, such as gasoline or diesel, to power an internal combustion engine or other propulsion source. Using electricity from the grid to run the vehicle some or all of the time reduces operating costs and petroleum consumption, relative to conventional vehicles. PHEVs might also produce lower levels of emissions, depending on the electricity source.

All-Electric Vehicles (EVs)

All-electric vehicles (EVs) use a battery to store the electrical energy that powers the motor. EVs are sometimes referred to as battery electric vehicles (BEVs). EV batteries are charged by plugging the vehicle into an electric power source. Although most U.S. electricity production contributes to air pollution, the U.S. Environmental Protection Agency categorizes all-electric vehicles as zero-emission vehicles because they produce no direct exhaust or emissions. Because EVs use no other fuel, widespread use of these vehicles could dramatically reduce petroleum consumption.

Benefits of Electric Transportation

1) Energy efficient: Electric vehicles convert more electrical energy from the grid to power at the wheels than conventional gasoline vehicles.

2) Environmentally friendly: EVs emit no tailpipe pollutants.

3) Performance Benefits: Electric motors provide quiet, smooth operation and stronger acceleration and require less maintenance.

Reduce Energy Dependence: Electricity is a domestic energy source.

Benefits of Fueling

EVs have the benefit of flexible fueling. They can charge overnight at a residence, workplace or at public charging stations. Public charging stations are not as universal as gas stations but charging equipment manufacturers, utilities, municipalities and government agencies are establishing a rapidly expanding network of charging infrastructure.

Residential equipment frequently will be installed in garages, but outdoor installation and use are also safe, even if the vehicle is being charged in the rain. Outdoor installations require outdoor-rated charging equipment. Charging at a multi-family residential complex requires additional considerations and may be more similar to public charging than to charging at a single-family home.

Emissions Reductions

Hybrid and plug-in electric vehicles can have significant emissions benefits over conventional vehicles. HEV emissions benefits vary by vehicle model and type of hybrid power system. EVs produce zero tailpipe emissions, and PHEVs produce no tailpipe emissions when in all-electric mode.

The life cycle emissions of an EV or PHEV depend on the sources of electricity used to charge it, which vary by region. In geographic areas that use relatively low-polluting energy sources for electricity production, plug-in vehicles typically have a life cycle emissions advantage over similar conventional vehicles running on gasoline or diesel. In regions that depend heavily on conventional fossil fuels for electricity generation, PHEVs and EVs may not demonstrate a strong life cycle emissions benefit. Use the Vehicle Cost Calculator to compare life cycle emissions of individual vehicle models in a given location.

Electric Vehicle Resources

|

|

From the U.S. Department of Energy Alternative Fuels Data Center

Alternative Fueling Station Locator – Find an alternative fuel station any time anywhere. State Laws and Incentives – Find tax credits and incentives in your state. Qualified Plug-In Electric Vehicle (PEV) Tax Credit – Plug-in hybrids and all-electric vehicles qualify for a $2,500 to $7,500 federal tax credit. A Homeowner’s Guide to Electric Vehicle – If your home is equipped to charge an EV, it might be an excellent choice for a vehicle. |

Ethanol

|

What is ethanol? Ethanol is a natural, non-toxic alcohol that burns clean and reduces greenhouse emissions by as much as 59 percent. It’s made in America, in rural farming areas all across the country. |

|

How is it made?

Ethanol is made from crops and other plant material grown right here in the U.S. Most is currently made from field corn, but new technologies are allowing ethanol to be made from other materials such as switchgrass, wood chips and agricultural waste. Standard corn ethanol uses the starch in the corn kernel – the rest of the proteins and nutrients are saved and used as a valuable livestock feed called distillers grains. Recent studies using updated data about corn production methods demonstrate a positive energy balance for corn ethanol, meaning that fuel production does not require more energy than the amount of energy contained in the fuel.

There are several steps involved in making ethanol available as a vehicle fuel:

- Biomass feedstocks are grown, collected and transported to an ethanol production facility

- Ethanol is produced from feedstocks at a production facility and then transported to a blender/fuel supplier

- Ethanol is mixed with gasoline by the blender/fuel supplier to make E10, E15 or E85, and distributed to fueling stations.

The benefits of ethanol?

Economy

The U.S. Department of Energy estimates for every one billion gallons of ethanol produced, 10,000 to 20,000 jobs are added to our domestic economy. In 2014 alone, the ethanol industry created and supported nearly 400,000 new jobs across the country that cannot be exported or outsourced. In addition, ethanol production contributed nearly $53 billion to the nation’s GDP and generated $5.7 billion in federal tax revenues. Ethanol production also plays a critical role in revitalizing America’s rural areas — some of the hardest hit by the economic downturn — by stimulating economic growth.

According to the Department of Energy’s Argonne National Laboratory, ethanol reduces greenhouse gas emissions by an average of 34 percent in comparison to gasoline. Moreover, advanced biofuels have the potential to reduce greenhouse gas emissions by over 100 percent. Ethanol from any source has a positive net energy balance — meaning it gives more energy than is needed to produce it.

In 2014, the 13.4 billion gallons of ethanol blended into gasoline in the United States helped reduce greenhouse gas emissions from on-road vehicles by approximately 38 million metric tons, which is the equivalent of removing roughly 8 million automobiles from the road. Imagine if we were using more ethanol in our motor fuels.

Ethanol is already replacing millions of barrels of imported petroleum. That’s petroleum that could have ended up in our environment, devastating coastal industries, ecosystems and communities. Ethanol is clean burning, renewable, and it’s grown right here in America.

The EPA estimates that higher Renewable Fuel Standards will reduce Greenhouse Gas Emissions from transportation by a total of 6.8 billion tons CO2 equivalent when measured over a 100-year timeframe. This is the equivalent of approximately 160 million tons CO2 equivalent per year. The overall reductions would be like removing 24 million vehicles from the road.

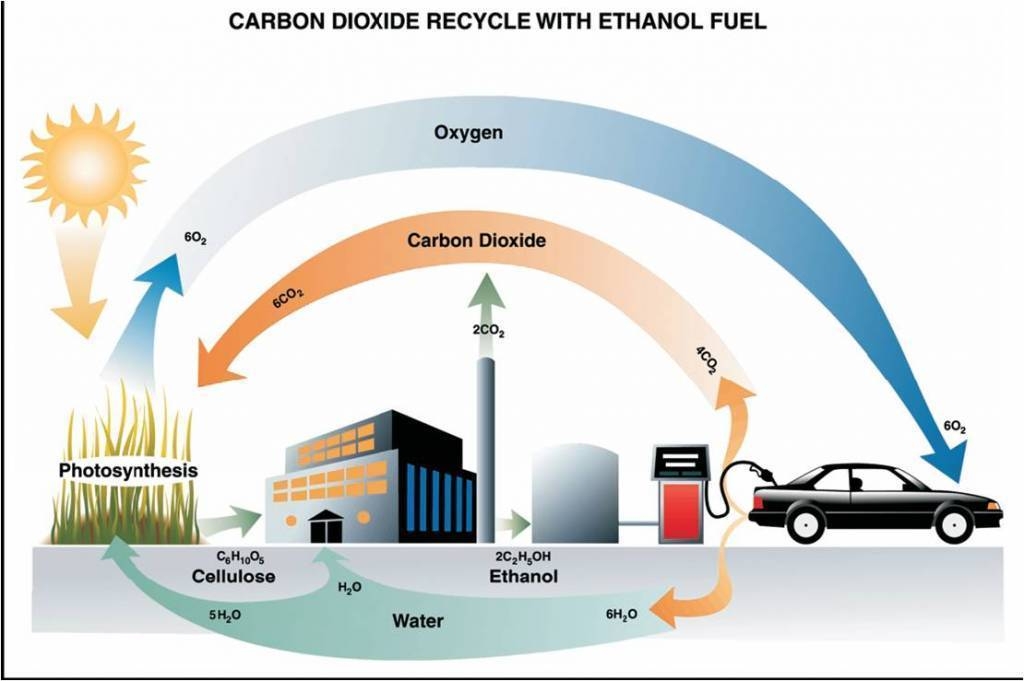

Emissions Reductions

The carbon dioxide released when ethanol is burned is balanced by the carbon dioxide captured when the crops are grown to make ethanol. This differs from petroleum, which is made from plants that grew millions of years ago. On a life cycle analysis basis, corn-based ethanol production and use reduces greenhouse gas emissions (GHGs) by up to 52% compared to gasoline production and use. Cellulosic ethanol use could reduce GHGs by as much as 86%.

Resources

Ethanol Basics, from the AFDC Website — A great starting point for learning about ethanol opportunities and technologies.

The American Coalition For Ethanol — A handy place to get involved and stay current on ethanol news.

Growth Energy — The nation’s premier trade association working to expand consumer access to ethanol-majority fuels.

Renewable Fuels Association – The RFA advocates for the ethanol industry and provides data and analysis to its members and the public.

E85Prices.com — An indispensable resource dedicated to tracking the price of E85 fuel nationwide.

Commonwealth Agri Energy and The Andersons, Inc. — Two American producers of ethanol products.

Fuel Freedom Foundation — An organization dedicated to reducing driving costs for your existing vehicle by supporting cheaper fuel choices.

American Coalition for Ethanol — An organization dedicated to uniting agricultural producers, businesses, and individuals in support of ethanol.

Ethanol Across America — An organization committed to advancing use of renewable fuels that can reduce oil imports and stimulate the economy.

Propane

Also known as liquefied petroleum gas (LPG) or autogas, propane is a clean-burning, high-energy alternative fuel that’s been used for decades to power light-, medium- and heavy-duty propane vehicles. It accounts for about 2% of the energy used in the United States. Of that, less than 2% is used for transportation fuel. Its main uses include home and water heating, cooking and refrigerating food, clothes drying, powering farm and industrial equipment.

WHAT IS PROPANE?

Interest in propane as an alternative transportation fuel stems mainly from its domestic availability, high-energy density, clean-burning qualities, and it’s relatively low cost. It is the world’s third most common engine fuel and is a domestically produced, well-established, clean-burning fuel. Typically, propane costs less than gasoline and offers a comparable driving range to conventional fuel and a lower fuel economy.

WHY WOULD A FLEET WANT TO USE BI-FUEL PROPANE VEHICLES?

Bi-fuel vehicles offer the benefit of allowing the driver/vehicles to venture anywhere, anytime. Since the vehicle can operate on gasoline while away from its home operating area, the vehicle isn’t restricted to only being able to refuel at home or where they can find propane on the road.

Low maintenance costs are another reason behind propane’s popularity for high-mileage vehicles. Propane’s high octane and low-carbon and oil-contamination characteristics have resulted in greater engine life than conventional gasoline engines. Because the fuel’s mixture of propane and air is completely gaseous, cold start problems associated with liquid fuel are reduced.

HOW IS IT PRODUCED?

Propane is produced from liquid components recovered during natural gas processing. These components include ethane, methane, propane, and butane, as well as heavier hydrocarbons. Propane and butane, along with other gases, are also produced during crude oil refining. Approximately 85% of the propane used in the U.S. is produced in the U.S.

Propane can be dispensed alongside gasoline, diesel, or other alternative fuels. It is brought to the site via a transport truck and put into onsite storage, traditionally above ground. The fueling dispenser is similar to a gasoline dispenser. The main difference is that propane is delivered to the vehicle under pressure so it remains a liquid. When the vehicle tank is full, the dispenser stops automatically, just like gasoline dispensers.

HOW IS IT USED?

There are light-, medium- and heavy-duty vehicles that can be powered by propane. Most propane vehicles used in the U.S. today are either bi-fuel or dedicated propane, and most are converted to bi-fuel propane using conversion kits like those that ICOM North America and Alliance Autogas offer. Applications include a wide variety of vehicles like cars, pickup trucks, forklifts, transit and school buses, delivery trucks, trolleys and delivery or passenger vans. Propane is also frequently used to replace gasoline in smaller applications, such as commercial lawn equipment like zero-turn and walk-behind landscaping mowers, and is growing in use as a golf/turf applications like for mowing golf courses (these are reel-type mowers).

WHAT ARE THE BENEFITS?

The Propane Green Autogas Solutions Act (“Propane GAS Act”) of 2011 offers significant economic growth, environmental and energy security benefits to the American economy, according to a study by the National Propane Gas Association. The study projects that the Propane Gas Act’s impact on jobs and the economy will be significant. The growth in propane vehicle sales and use created by the tax credits will generate an increase in economic activity that peaks at between $4 billion and $5.7 billion per year in 2016. That translates to between 30,000 and 42,000 new jobs created by 2016.

Propane is an inherently clean-burning fuel due to its lower carbon content. When used as a vehicle fuel, propane can offer life cycle greenhouse (GHG) emissions benefits over conventional fuels, depending on vehicle type, and drive cycle. In addition, using propane in place of petroleum-based fuels may reduce some tailpipe emissions.

Because propane is a low-carbon fuel, a switch to propane in these applications can result in substantial reductions of hydrocarbon, carbon monoxide, oxides of nitrogen, and greenhouse gas emissions.

EMISSION REDUCTIONS GAINED FROM PROPANE

Propane is non-toxic and presents no threat to soil, surface water, or groundwater. Propane has several benefits over gasoline including:

- Potentially lower toxic, carbon dioxide (CO2), carbon monoxide (CO), and nonmethane hydrocarbon (NMHC) emissions

- Over the fuel’s life-cycle, propane shows greenhouse gas (GHG) emission reductions of 10%, and when derived as a by-product of natural gas production (as it is over 90% of the time), propane reduced petroleum use by 98% to 99%

PROPANE INFORMATION & LINKS

The Propane section on the AFDC Website – Great starting point in learning about propane opportunities and technologies.

Propane Education & Research Council (PERC)

Propane Autogas Vehicle System Companies: ICOM North America, ROUSH CleanTech, Alliance AutoGas

Fuel Economy.gov’s propane page.

School administrators from Fairfax County, Montgomery County, Prince George’s County, Frederick County, Alexandria City, Arlington County, Howard County, Baltimore County, Washington County, Carroll County, Calvert County, Charles County and St. Mary’s County attended two propane and biodiesel school bus workshops in Fairfax County VA and Prince George’s County Maryland on May 23 and May 25 respectively. The events were a collaborative effort of the Greater Washington Region Clean Cities Coalition, the Maryland Energy Administration/Maryland Clean Cities and Virginia Clean Cities, along with the propane and biodiesel industries and school bus manufacturers.

Compressed Natural Gas

Natural gas is an odorless, nontoxic, gaseous mixture of hydrocarbons. It accounts for about a 25% of the energy used in the United States. About one-third goes to residential and commercial uses, such as heating and cooking; one-third to industrial uses; and one-third to electric power production.

ACRONYMS

CNG – compressed natural gas

LNG – liquefied natural gas

RNG – renewable natural gas (or CNG made from renewable sources like landfill gas or biomethane from digester operations).

CNG vehicles traveled from California to Washington D.C. to bring awareness of the benefits of natural gas in fleets

HOW IS IT PRODUCED?

CNG is produced by compressing natural gas to less than 1% of its volume at standard atmospheric pressure. To provide adequate driving range for a vehicle, Compressed Natural Gas (CNG) is stored in cylinders at a pressure of 3,000 to 3,600 pounds per square inch. A CNG-powered vehicle gets about the same fuel economy as a conventional gasoline vehicle on a gasoline gallon equivalent basis.

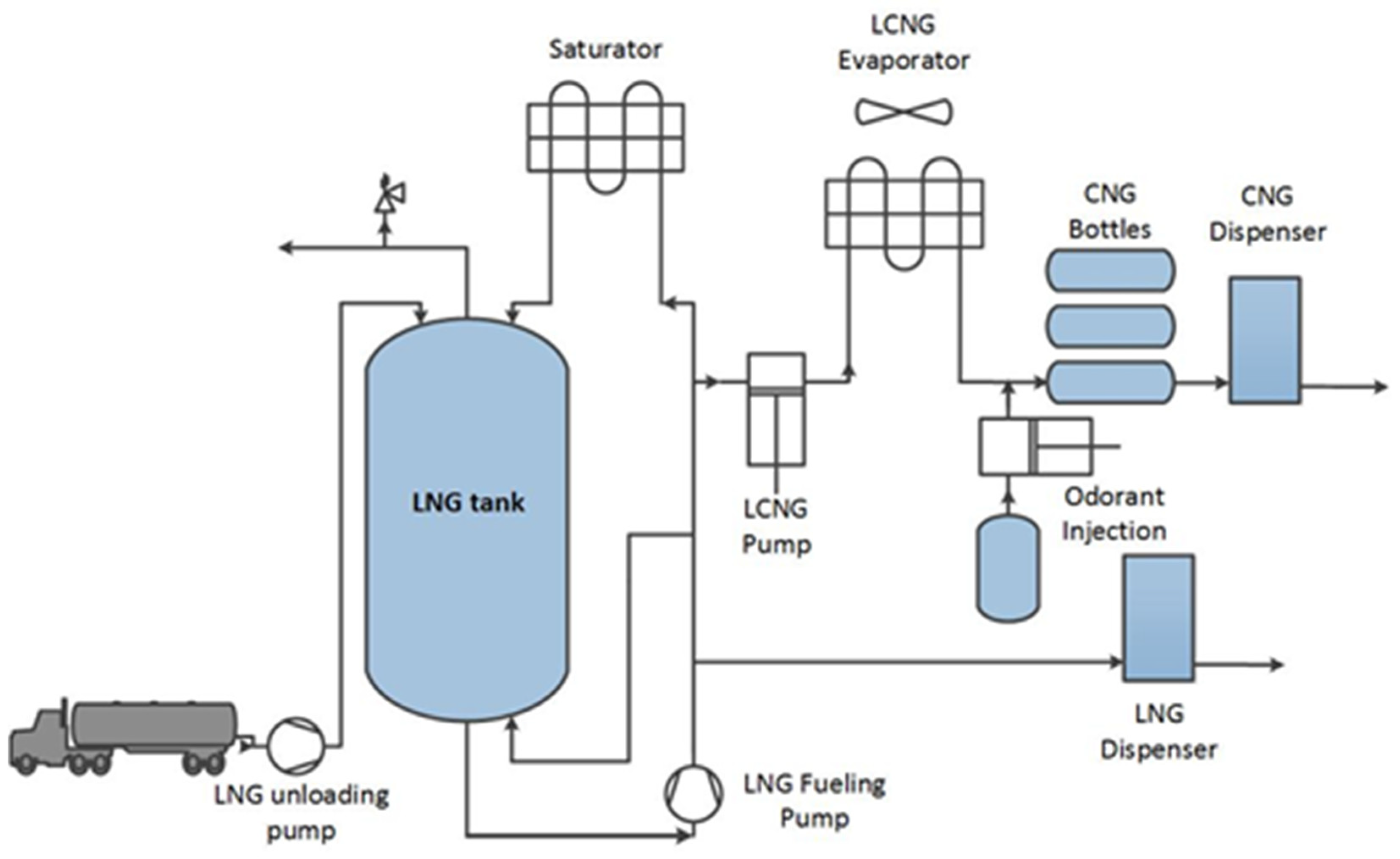

Liquefied natural gas, or LNG, is natural gas in its liquid form. LNG is produced by purifying natural gas and super-cooling it to -260°F to turn it into a liquid. During the process known as liquefaction, natural gas is cooled below its boiling point, removing most of the compounds found in the fuel.

Renewable natural gas (RNG), also known as biomethane, is produced from organic materials—such as waste from landfills and livestock—through anaerobic digestion. RNG qualifies as an advanced biofuel under the Renewable Fuel Standard. Because RNG is chemically identical to fossil-derived conventional natural gas, it can use the existing natural gas distribution system and must be compressed or liquefied for use in vehicles.

HOW IS IT USED?

Natural gas powers about 150,000 vehicles in the United States and roughly 15.2 million vehicles worldwide. Natural gas vehicles (NGVs) can run on compressed natural gas (CNG) or liquified natural gas (LNG). CNG is the most widely used option (as well as the most widely used alternative fuel) and is a good choices for high-mileage, centrally fueled fleets that operate within a city or regional area. For vehicles needing to travel very long distances, liquefied natural gas (LNG) enables the vehicles to go longer distances on natural gas. The advantages of natural gas as a transportation fuel include its domestic availability, low cost, growing infrastructure and inherently cleaner-burning qualities.

THERE ARE THREE TYPES OF NATURAL GAS VEHICLES

- Dedicated: These vehicles are designed to run only on natural gas and are spark-ignited (SI) engines.

- Bi-fuel: These vehicles have two separate fueling systems that enable them to run on either natural gas or gasoline, not both. The engines are almost always SI, and use a spark plug to provide the ignition point.

- Dual-fuel: These vehicles are traditionally limited to heavy-duty applications, and have fuel systems that run on natural gas and diesel at the same time. They are compression-ignition (CI) engines and use diesel as the “spark” for ignition, and typically burn on the order of 50% natural gas and 50% diesel.

For light- and medium-duty fleets, although there are a few OEM CNG vehicles on the market, most vehicles are conventional vehicles that are converted to run on natural gas. As you move into the heavy-duty market and the largest on-road vehicles used in the U.S. (think class-8 tractors, dump trucks, school buses), you find many more OEM products that are purchased directly from the vehicle manufacturers. Currently, about 12-15% of public transit buses in the U.S. run on natural gas.

WHAT ARE THE BENEFITS OF USING NATURAL GAS

Compressed and liquefied natural gas are clean, domestically produced alternative fuels. Using these fuels in natural gas vehicles increases energy security and can lower emissions. The driving range of non-gas vehicles is generally less than that of comparable gasoline and diesel vehicles because with natural gas, less overall energy content can be stored in the same size tank as the more energy-dense gasoline or diesel fuels.

Natural gas is safely and responsibly developed in 31 states across the United States, and it is putting Americans to work in all 50 states. How many jobs? IHS Global Insight estimates that as of 2008, total natural gas production supported more than 2.8 million jobs in the United States. Increasing the development of our nation’s unconventional sources of gas alone will add more than 1.4 million U.S. jobs by 2015. A recent study by PricewaterhouseCoopers for the National Association of Manufacturers forecasts an additional 1 million U.S. jobs in manufacturing by 2025, thanks to our nation’s vast, affordable supplies of natural gas.

Compared with vehicles fueled by conventional diesel and gasoline, natural gas vehicles can produce lower levels of some emissions. And because CNG fuel systems are completely sealed, CNG vehicles produce no evaporative emissions. Natural gas is increasingly used to replace gasoline in smaller applications, such as in forklifts and commercial lawn equipment. Because natural gas is a low-carbon, clean-burning fuel, a switch to natural gas in these applications can result in substantial reductions of hydrocarbon, carbon monoxide, oxides of nitrogen, and greenhouse gas emissions.

WHAT ARE THE EMISSION REDUCTIONS GAINED FROM NATURAL GAS?

Light-duty vehicles running on compressed natural gas (CNG) and liquefied natural gas (LNG) emit approximately 6%-11% lower levels of greenhouse gases than gasoline powered vehicles throughout the fuel life cycle.

Natural gas produced via renewable methods offers additional benefits. Renewable natural gas (RNG) is essentially biogas—the gaseous product of the decomposition of organic matter—that has been processed to purity standards. Capturing biogas from landfills and livestock operations reduces emissions by preventing methane release into the atmosphere. Methane is 25 times stronger than carbon dioxide as a greenhouse gas. Additionally, producing biogas through anaerobic digestion reduces odors and produces nutrient-rich liquid fertilizer.

Natural Gas…

- Reduces carbon dioxide emissions 10-15%; for RNG that numbers shoots to over 80%

- Emits little or no particulate matter (e.g., PM-10, PM-2.5); the reductions are massive as compared to pre-2008 diesel vehicles

- Reduces carbon monoxide emissions 50%-97%

- Reduces nitrogen oxide emissions 35%-60%

- Emits fewer toxic and carcinogenic pollutants

- Reduces non-methane hydrocarbon emissions 50%-75%

- Emits little or no particulate matter

- Virtually eliminates evaporative emissions

- The Natural Gas section on the AFDC Website – Great starting point in learning about natural gas opportunities and technologies.

- NGVAmerica is the national trade association dedicated to the development of a growing and sustainable market for vehicles powered by natural gas or biomethane.

- Light- & Medium-Duty CNG Vehicle System Companies: Altech-Eco, Landi Renzo, Power Solutions Int’l, Westport, STAG Alt Fuel Systems, AGA Systems

- Fuel Economy.gov’s Natural Gas page

- www.CNGprices.com is the only website where you can a map of all the CNG stations in the USA that INCLUDES pricing information for almost every station.

- Freightliner’s CNG website where they discuss the different kinds of class-8 daycab and vocational trucks they offer in CNG (there is also a sleeper cab section of the site)

- The Natural Gas Vehicle Institute which offers numerous training courses and opportunities to educate all kinds of workers on natural gas, NGVs and refueling systems

HYDROGEN

Hydrogen is the most abundant element in the universe. Because it does not exist in its molecular form on earth, it must be first extracted from another compound, such as water or methane using renewable electricity or carbon-abated fossil fuels. Hydrogen then acts as an energy carrier and storage device, helping to generate electricity or heat when combined with oxygen through a fuel cell or combusted.

Hydrogen produces zero emissions at point of use, so for example, a fuel cell electric vehicle that runs on hydrogen produces no tailpipe emissions. A versatile, clean, and safe energy carrier, hydrogen can be used as fuel for power generation or in industry as feedstock. And due to its energy density, it is currently the only zero-emission technology capable of producing the extreme heat necessary to produce cement, steel, glass, and other industrial materials.

Hydrogen can enable large-scale, efficient renewable energy integration into the power grid, utilize existing pipeline infrastructure to distribute energy across sectors and geographies, and decarbonize transportation, industry, heating, and other sectors.

Trusted Partners

“Coming together is a beginning, staying together is progress, and working together is success.” – Henry Ford